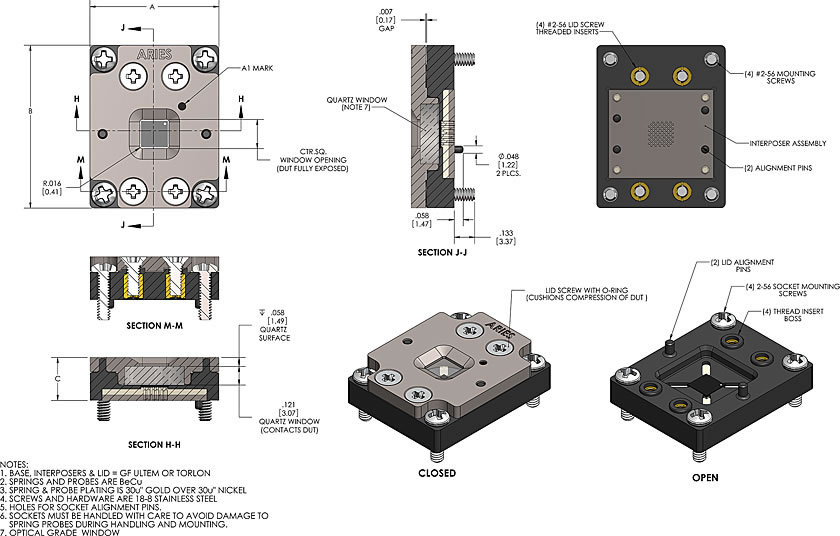

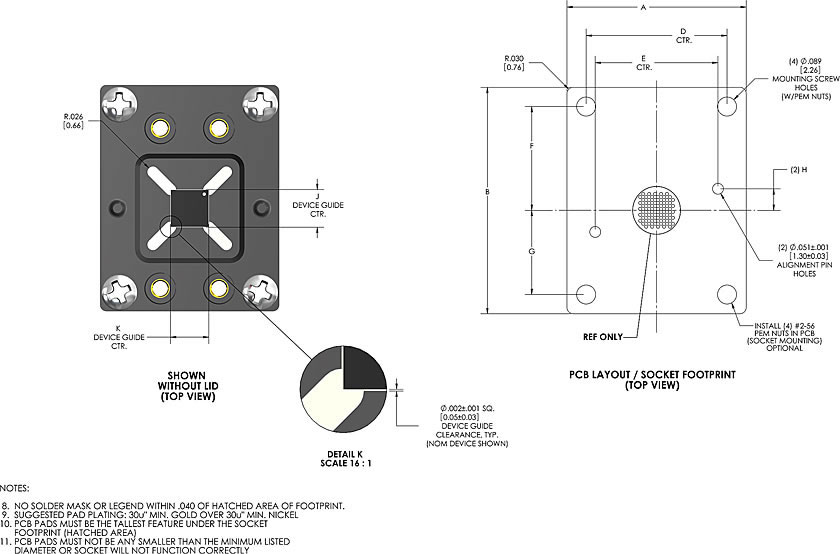

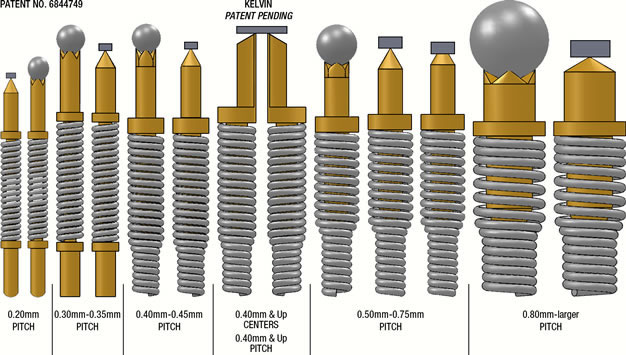

ALL DIMENSIONS: INCHES [MILLIMETERS]

ALL TOLERANCES: ±0.005 [0.13] UNLESS OTHERWISE SPECIFIED

CONSULT FACTORY for DIM. “A” – “K”

CONSULT FACTORY FOR OTHER SIZES AND CONFIGURATIONS

PRINTOUTS OF THIS DOCUMENT MAY BE OUT-OF-DATE AND SHOULD BE CONSIDERED UNCONTROLLED

CUSTOMIZATION: In addition to the standard products shown on this page, Aries specializes in custom design and production. Special materials, platings, sizes, and configurations can be furnished, depending on quantity. NOTE: Aries reserves the right to change product specifications without notice.